Driven Soil Nail Walls

The Driven Soil Nail shoring system consists of driven steel bars with a composite geotextile fabric and wire mesh face, improving installation time by 50% over conventional shoring methods.

Driven Soil Nail vs Drilled Soil Nail Comparison Sheet

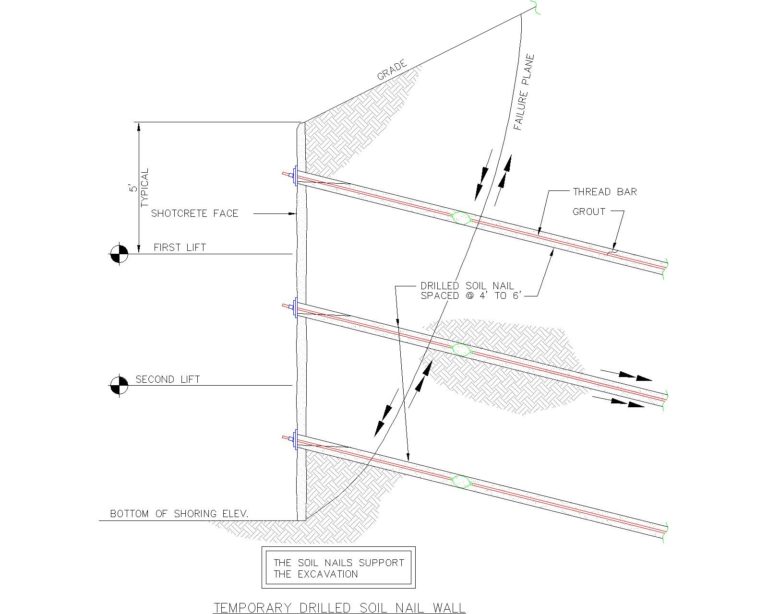

- Temporary excavation shoring

- Slope stabilization

- Excavate 5 feet

- Place geocomposite wall face

- Drive steel bars

- Proof test driven nails

- Repeat process to bottom of excavation

Testimonials

Due to the location of the project, North Carolina State University, I was very impressedat the crews manners and respect for their surroun dings. They acted very professionally.

Subsurface has always been good to work with and this project was no exception! look forward to working with you guys in the future.

We wish all subcontractors were as professional and cooperative as your team.

Subsurface was enjoyable to work with on a daily basis on a project which had many moving parts and difficult interaction between trades. Very responsive and made effort to be effective in completing the required scope of work.

The Subsurface Construction team exceeded our expectations in every phase of the project. When challenges presented themselves, the field and office teams were proactive in overcoming them and stayed on schedule. From the bottom to the top, they are driven..

The field Teams did all they could to expedite and work as hard as possible. Robert, Chuck, and Jeff all worked well with myself and BBC field team. I am pleased to have had the opportunity to meet and work..

Due to our tight schedule we needed Subsurface to expedite design. Subsurface came through for us and we met the schedule and satisfied our challenging owner.

Subsurface was very well organized and their Salety program went beyond expectations. Great job!

An excellent member of our team... RN Rouse and the owner were vey pleased with their efforts in nmaking the beginning phases of this project a success.

When we need a soil nail wall sub again, I highly recommend Subsurface. They worked with our ever changing schedule without complaining.